Salt Manufacturing in Tuticorin: Process, Types, and Industry Insights

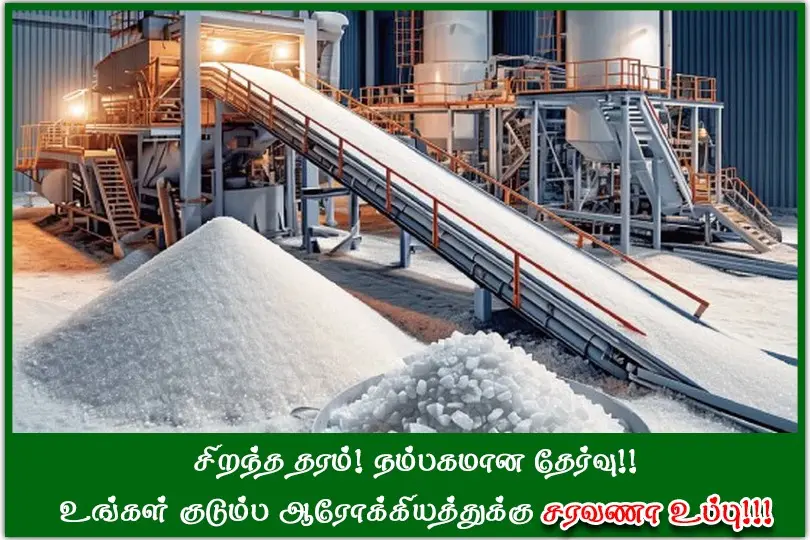

Salt Manufacturing in Tuticorin is one of the most critical industries in the region, contributing significantly to the local economy and national supply. Tuticorin’s coastal location, flat terrain, and abundant sunshine make it an ideal hub for producing high-quality salt. The industry combines traditional solar evaporation methods with modern mechanized techniques to meet domestic and industrial demands.

Salt may seem simple, but behind every crystal lies the combined effort of nature, tradition, and human labor—making Salt Manufacturing Tuticorin not just an industry, but a story of dedication, community, and sustainable growth.

– Saravana Salt Team

How Salt Manufacturing in Tuticorin Works

Salt Manufacturing Tuticorin primarily relies on solar evaporation, which is both eco-friendly and cost-effective. The process includes:

- Seawater Collection: Seawater is collected in large shallow ponds known as salt pans.

- Evaporation: The sun naturally evaporates water, leaving behind salt crystals.

- Harvesting: Salt crystals are harvested manually or using mechanized tools.

- Processing and Refining: Salt is washed and sometimes refined for higher purity.

- Packaging and Distribution: The processed salt is packed and supplied to various industries.

Modern salt manufacturing plants in Tuticorin use advanced technology to improve efficiency while maintaining high-quality standards.

Types of Salt Produced in Tuticorin

Salt Manufacturing Tuticorin produces various types of salt for multiple applications:

- Edible Salt: Refined for cooking, table use, and processed foods.

- Industrial Salt: Used in chemicals, soap production, and textiles.

- Solar Salt: Naturally evaporated salt used in both food and industrial sectors.

Uses of Salt Manufacturing in Tuticorin Products

The salt produced in Tuticorin serves several industries:

- Food Industry: Table salt, snacks, and processed foods.

- Chemical Industry: Production of caustic soda, chlorine, and other chemicals.

- Pharmaceuticals: Saline solutions and medicines.

- Industrial Applications: Water treatment, leather, and textile processing.

Economic Impact of Salt Manufacturing in Tuticorin

Salt Manufacturing Tuticorin employs thousands of workers in the region. The industry supports livelihoods and contributes significantly to India’s salt exports, generating foreign revenue and boosting the local economy.

Environmental Considerations

While Salt Manufacturing Tuticorin is eco-friendly mainly due to solar evaporation, there are some environmental challenges:

- Salt pans may affect local soil and water ecosystems.

- Overharvesting can disturb nearby habitats.

- Modern plants are adopting sustainable practices to minimize ecological impact.

about Salt Manufacturing in Tuticorin

Q1: Why is Tuticorin ideal for salt manufacturing?

A1: Tuticorin’s coastal location, flat terrain, and high sunshine hours make it perfect for Salt Manufacturing in Tuticorin.

Q2: What is the primary method used in Salt Manufacturing Tuticorin?

A2: The primary method is solar evaporation, where seawater is evaporated to produce salt crystals.

Q3: How is the harvested salt processed in Tuticorin?

A3: After harvesting, the salt is washed to remove impurities and may be refined for higher purity.

Q4: Which industries rely on Salt Manufacturing Tuticorin?

A4: Food, chemical, pharmaceutical, textile, and water treatment industries rely heavily on Tuticorin salt.

Q5: Is Tuticorin salt exported internationally?

A5: Tuticorin contributes significantly to India’s salt exports, supplying high-quality salt to global markets.

Q6: Are there environmental concerns in Salt Manufacturing Tuticorin?

A6: While mostly eco-friendly, salt pans can affect soil and water ecosystems. Modern plants are adopting sustainable practices to reduce this impact.